A story of care, craft, and concrete. Scroll to See How it's Done

Chapter One: The Research

Where the building begins again

Before anything is made, I spend time getting to know the building. Sometimes it’s one I’ve known for years, sometimes it’s a new discovery. I look through architectural drawings, planning documents, obscure photos. I walk around it, climb it if I can, stare at it from strange angles. I try to understand not just how it looks, but how it feels.

It’s a slow kind of looking. An attempt to honour the original architect’s intent, while also making space for my own relationship with the building. I try to fill myself up with the building, and then left it pour out into my work.

"I spend hours adjusting proportions, testing scale, and problem-solving"

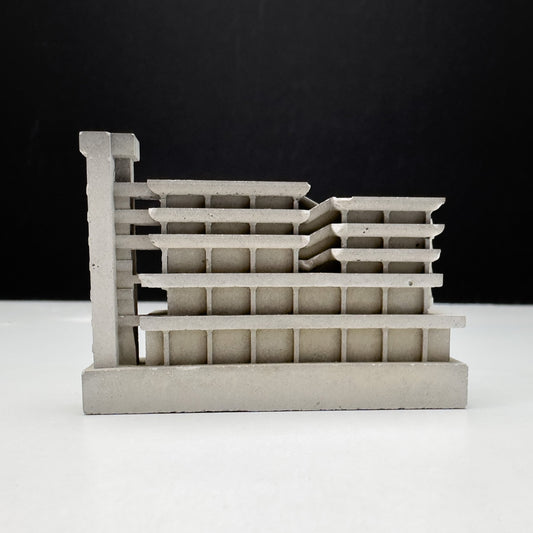

Chapter Two: The Digital Model

Where everything is built, virtually, first

Next, I create a 3D model using architectural software. Every line, angle, and void is carefully constructed from scratch.

This isn’t about shortcuts. It’s about fidelity. I spend hours adjusting proportions, testing scale, and problem-solving the structure so it can be translated into physical form.

It’s not always straightforward. Brutalist buildings weren’t made to be miniaturised. But this stage is one of my favourites.It's full of thinking, decisions, and invisible architecture.

Chapter Three: The Print Setup

From file to form with a lot of tinkering in between

Once the digital model is ready, I prepare it for resin 3D printing. This stage is technical and unpredictable. Supports need to be placed precisely. Angles need to be reconsidered. Sometimes things fail, layers peel, structures warp, details are lost. We go again.

It takes care and knowledge to dial in the settings just right. But when it works, it’s magic. A building begins to exist, tentatively, in translucent resin. Ready to become solid.

there’s something beautiful and almost therapeutic about this part of the process

Chapter Four: The Moulds

Pouring time into every detail

After 3D printing, the silicone rubber moulds are made. The mixture is whisked up and then carefully poured by hand to capture fine architectural details without creating bubbles, traps, or weak points.

Mould-making is a quiet art. It’s slow and hands-on. But there’s something beautiful and almost therapeutic about this part of the process.

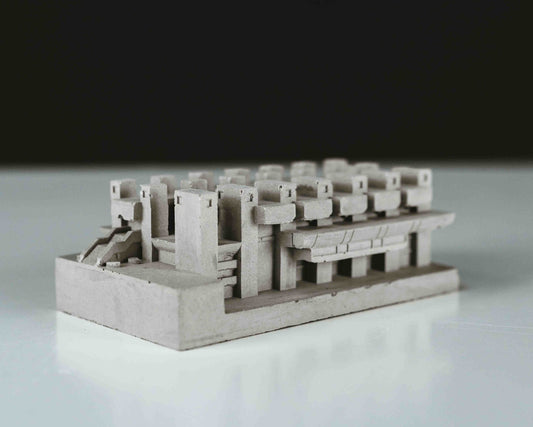

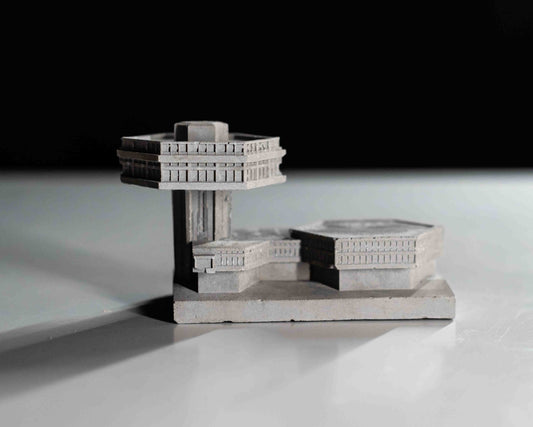

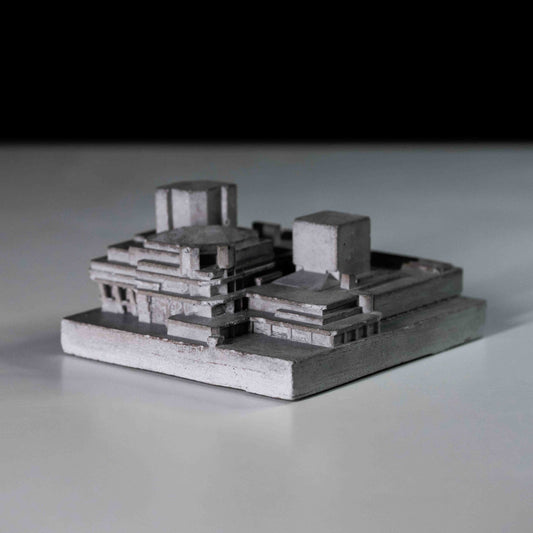

Chapter Five: The Concrete Cast

Hands in the mix

I use a specialist blend of fine concrete, mixed and poured in small batches. Each piece is cast slowly and vibrated and pressure-cured to improve the level of detail.

Concrete has a mind of its own. Each pour is a little different. Each model carries its own unique surface. Subtle temperature and humidity changes affect the curing process, and tiny imperfections will be distinct to each model, that makes it feel alive.

Sometimes it doesn't work at all. But through practice and persistence, I've gotten to know concrete's own mind.

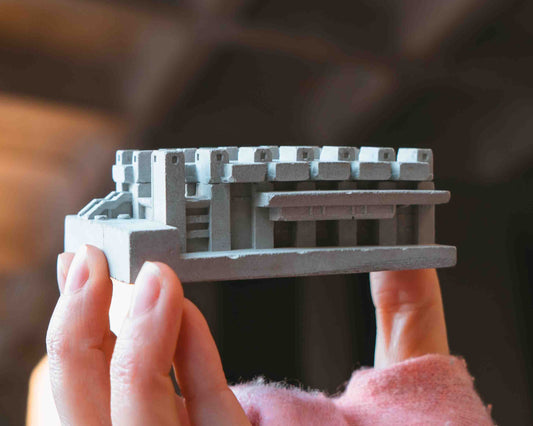

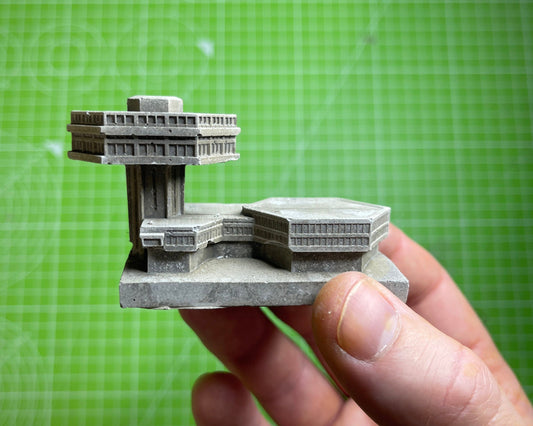

Chapter Six: The Finish

Every model is checked, held, and held again

Once demoulded, every model is examined carefully. It’s sanded, smoothed, and checked again. Laser cut and etched cork is added to the base of the model showing the building's name. Then it's carefully packed into a customised giftbox, like a precious jewel.

I don’t make hundreds a day. I don’t want to. What matters is that every object feels intentional.

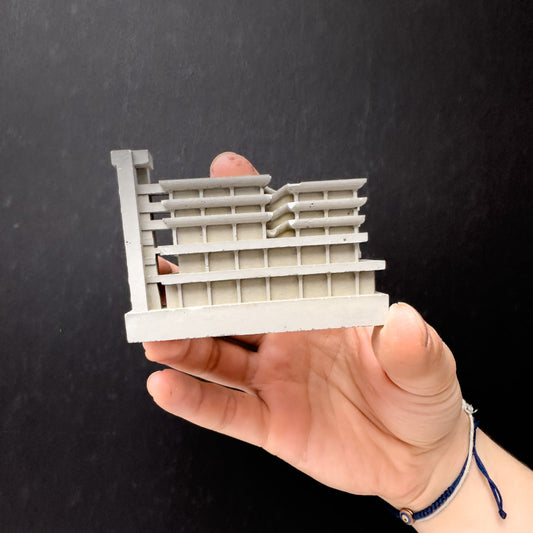

Chapter Seven: The Why

We’re not machines. We’re humans.

Every part of this process is done by real people working with our hands, thinking hard about things most people wouldn’t notice. We do it because we care.

We care about the presence and history of these buildings. We care about the strange joy in making things slowly and well. And we care about the people who receive our work, the ones who understand what these buildings mean, and why it matters to hold something solid in your hands.

This is craft production. Made slowly, with care and intention. From obsession, and from love. To be shared, and to bring us together.

Hold a Memory in the Palm of Your Hand as a Miniature Brutalist Model

Want to Find Out More?

Click on the links below for even more insights